Context

PRODUCTION OF INDUSTRIAL GOODS WILL BE COMPLETELY DIFFERENT IN THE FUTURE than it was up to now. IN THE PILOT FACTORY AT TU Wien, RESEARCH IS Conducted about how intelligent production works.

Manufacturing products today is more than just setting up a machine and pressing the big green button. Industrial production is becoming increasingly complicated and interconnected. In the future, individual work steps will no longer be looked at separately from one another in production, but all areas of production will be interconnected through information technology and coordinated with one another. The TU Wien is now taking an important step into the new age of production – in the Pilot Factory at TU Wien research and testing is carried out to determine how the industry of tomorrow should look like.

Internet of things

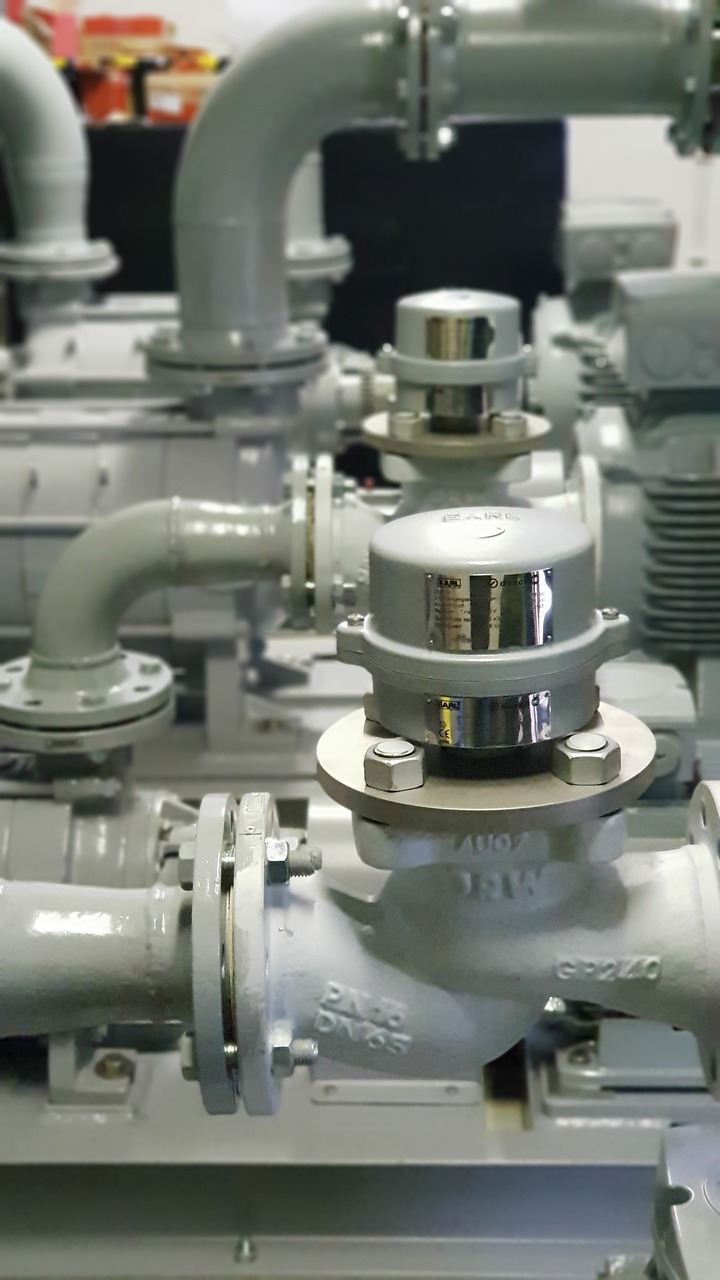

In the future, smart IT systems will ensure that different machines are coordinated with one another and react to each other – which is related to as ‘Industry 4.0’ or ‘Smart Production’, based on the ‘Internet Of Things’ or cyber-physical systems. Neither idling, f.e. caused by the lack of required components, nor inventory costs, caused by overproduction at one step of the process, are supposed to occur; outages and failures are expected to be handled discreetly by the system. Strategy will not be managed manually at a control center, but will essentially be supported by the communication of machines. Auxiliary industries as well as distribution will be incorporated by the integral system. That comes with many advantages: production is going to be faster, cheaper and increasingly energy-efficient. Furthermore, it will be easier to meet individual customer requests. Individually fitted products are harder to manufacture than mass products, which is why the TU Wien is working on strategies for manufacturing personalized products in very small batch sizes efficiently. Continuous digital images of products and the production system are crucial.

Practical experimentation in the Pilot Factory

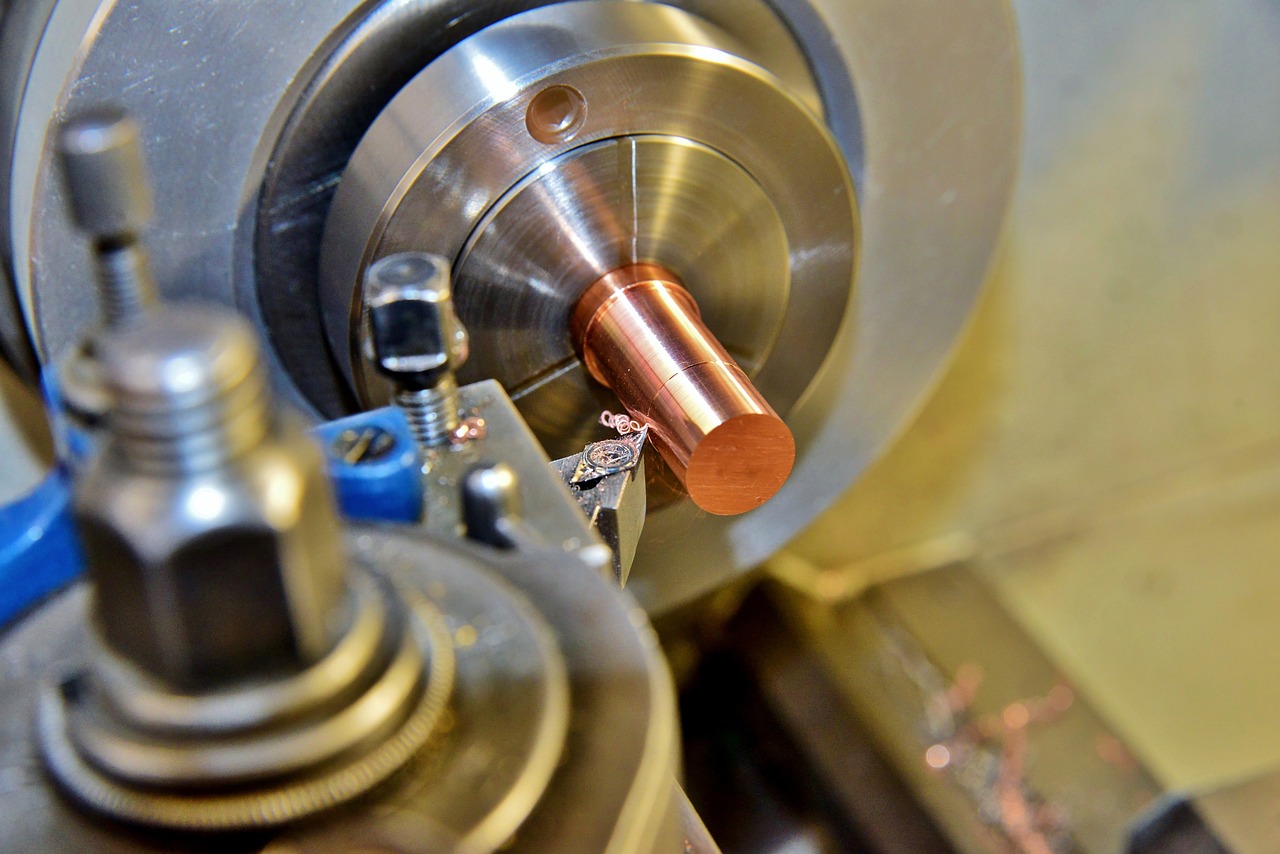

In order to be able to develop, test and improve such new strategies for the industry, one needs a realistic test environment – real machines, real production chains and also a real product.

In the Pilot Factory at TU Wien, the decision was made to use components from 3D printers, because these are relatively complex objects that can be produced in a large number of variants. The production is therefore sufficiently challenging to be scientifically interesting.

Ideas for the industry

The Pilot Factory is important for several reasons: Scientific know-how about optimal production techniques should be developed, which will then benefit the economy. At the same time, the Pilot Factory plays a decisive role in teaching at the TU Wien. There, the students can get to know the entire supply chain and help develop it – from construction to production and assembly to quality assurance and logistics. It should be possible there to develop new prototypes and new process technologies. Last but not least, the Pilot Factory should also be used for further training – specialists in production should get to know new ideas there, which they can then implement in their own companies.

RE-INDUSTRIALIZATION OF EUROPE?

It is indisputable that production technology is changing worldwide. It is inevitable that jobs will also be lost as a result of increasing automation. Nevertheless – or perhaps because of this – it is important for Europe to rely on modern production techniques. Improved production can ensure that outsourced production processes are brought back to Europe. Flexibility, adaptivity and the ability to quickly turn a product into production are often more important than low labor costs. Industry 4.0 can strengthen the European production sector and lead to re-industrialization.

Goals

The Pilot Factory Industry 4.0 pursues three main areas.

Research

Education

knowledge transfer

The main areas of the TU Wien Pilot Factory Industry 4.0 focuses on the discrete, multi-variant series production up to the production in very small quantities (lot size 1, “high-mix and low-volume”). All aspects of product creation from design to assembly are included in an integrative approach. The topics that are addressed both in research and in training, in the context of demonstration scenarios, are dedicated to current issues from the industry and are intended to represent possible solutions.

BUSINESS SECTORS

on which this content orientation focuses.

The target group are especially small and medium-sized companies. Their needs and fields of interest are determined by the participating institutes within the framework of close cooperation contacts.